Driving-in shelf is an assembled shelf in which forklift trucks drive into and out of the shelf and store goods in pallet units. Driving-in shelf, also known as corridor shelf and through shelf, is a multi-door, pallet unit cargo structure connected by lattice column side-by-side, which is stored on the cantilever beam one by one along the depth direction. This kind of shelf structure can share the forklift truck operation channel and goods storage space, greatly improving the space and space utilization ratio of warehouse, but the goods in the same operation channel can not be first in first out. It is suitable for large quantities, small varieties or goods in the operation channel to flow to the same customer's goods storage together, such as beverages, dairy products, tobacco, cryogenic storage, and so on. Standard specifications of household appliances, chemical industry, clothing and other industries. According to statistics, driving shelves can achieve maximum storage density, the most effective utilization of space can be increased to 90%, and the utilization of site area can reach more than 60%.

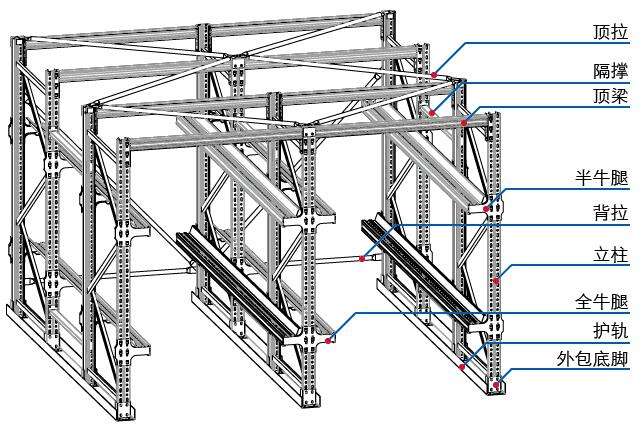

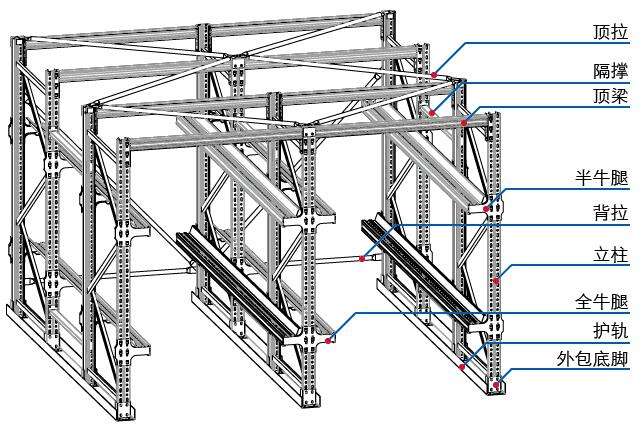

Structural characteristics of driving shelves:

1. On the support rail, the pallets are stored in the depth direction, one after another, which makes high density storage possible.

2. Goods are accessed from the same side of the shelf and stored first and then taken out. Balanced weight and forward forklift trucks can easily enter the shelf to access goods without occupying multiple channels.

3. This kind of shelf is suitable for storing large quantities and few varieties of goods.

4. Full-insertion assembly structure of driving rack, column piece is assembly structure, the total depth of rack in wall area can be designed to be less than 7 pallet depths, and the total depth of shelf in middle area can be less than 9 pallet depths, so as to improve the efficiency and reliability of forklift truck access.

5. Widely used in various warehouses and logistics centers such as food, tobacco, dairy, beverage and other industries, cold storage is also more common.

Attentions for procurement of driving shelves:

1. Understanding the size of the pallet, the direction of fork entry, the carrying capacity of the pallet and the maximum weight of the goods to be stored in each pallet location.

2. Warehouse size, height, location of fire hydrant, location of entrance and exit, etc.

3. Forklift comprehensive data, maximum lifting, maximum weighing, forklift width, etc.

Provide intelligent warehousing logistics equipment solutions business.

Provide intelligent warehousing logistics equipment solutions business. Continue to explore the possibility of user experience

Continue to explore the possibility of user experience Our service is not a slogan, a concept or an advertisement. Our service is serious.

Our service is not a slogan, a concept or an advertisement. Our service is serious. You are welcome to call for information or appointment.

You are welcome to call for information or appointment.