Storage rack with small bin

AS/RS High-level Shelf Technology for Storage Project

1. Content of Entrustment

Maximum Outward Size of Unit Goods (Container):L600(mm)*W400(mm)*H140/300(mm);

Unit cargo maximum weight (containers):50kg;

Unit space holds rated load (containers):100kg(2 shipping space);

Unit space size: L670 (net length)*D900×H250mm

The total shelf height H = 3400mm (without cushion beam height 100mm, subject to final signature drawing);

The takeover height of the first and the first floor of the double-deep shelf is 550 mm (counting from the side near the roadway), whichever final drawing will be signed shall prevail;

Shelf size: 8 rows * 100 rows * 9 storeys = 7200 cargo spaces, including 800 high cargo spaces (2 roadways);

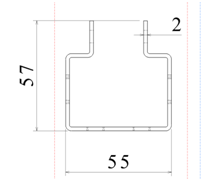

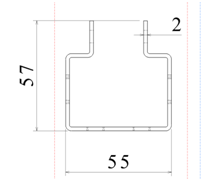

Column type: The column adopts 55W, section size is 5557 series, thickness is 2.0mm, Q235;

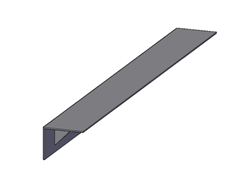

Column section | Pillar effect map |

|

|

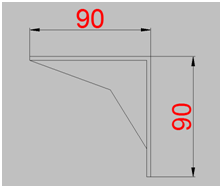

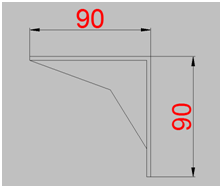

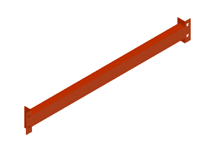

9.The bracket is made of bending profiles with a cross-section size of 900*90*90 series and a thickness of 3.0mm.

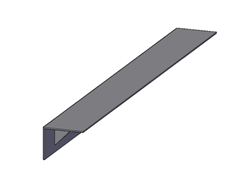

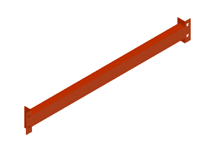

Bracket Beam | Bracket beam effect drawing

|

|

|

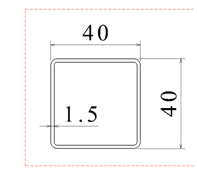

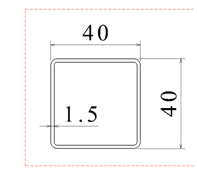

10.Shelf crossbeam, 40*40*1.5 square pass.

Beam | Beam effect drawing

|

|

|

11.Protective net should be installed on the outside of the shelf. The protective height is H=1200mm, the structure of steel wire mesh is made up of 40*40mm mesh hole, 2.0mm diameter of steel wire and Q235 material. The final signature shall prevail.

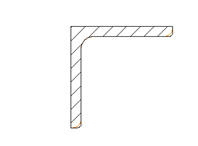

12.Skyway type: angle steel 80 *80 *6 mm;

Sky rail |

|

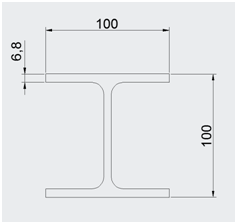

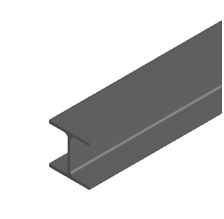

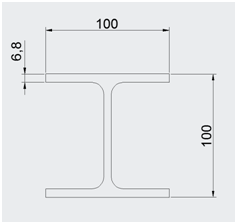

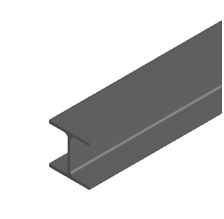

13.Ground rail model: H-type rail 100*100*6.8; ground rail pad 10mm black rubber block, both ends of the ground rail contain mechanical blockers, and ultimately will be based on the signature map.

Ground rail | Ground Orbit Effect Map |

|

|

14.The base of the rack and the ground rail are connected with the ground by foot bolts.

2. Design Basis

Drawing Basis: Plan of Automated Stereo Warehouse Provided by Party A

Standard: CECS23:90 Code for Design of Steel Shelf Structures

JB/T9018-99 Code for design of high-rise rack warehouse with rail roadway

JB/T11270-2011 Technical Conditions for Composite Steel Structure Shelf of Stereoscopic Warehouse

GB50011-2001 Chinese Code for Seismic Design

The seismic fortification intensity is 6 degrees, the design basic earthquake acceleration value is 0.05g, and the design earthquake is grouped into the first group.

3. Shelf requirements

The following conditions should be satisfied under full load of the rack cross beam.

Prestress is not allowed.

No residual deformation is allowed.

The shelf material is made of well-known steel products in China, and the main material is Q235.

Standard parts are of grade 8.8 except anchor bolts and locking nuts.

The color is as follows:

4. Manufacturing Technology of Shelf

The surface of the weld seam of the components shall be welded evenly, and there shall be no defects such as cracks, slag inclusion, welding nodules, burning through, arc pits and needle-like air holes.

The limit error of shape and dimension of fillet weld and weld seam should conform to the relevant provisions of GBJ205.

The shelf surface is degreased, phosphated, washed, dried and electrostatic sprayed. The coatings are made of thermosetting epoxy resin (powder), with an average thickness of 60 microns. The quality of the coatings is in accordance with the GB6807-86 standard, which ensures that the coatings are full and smooth, colorless, and do not allow shrinkage, wrapping and other phenomena.

5. Processing Accuracy of Shelf

The spacing error of the connecting holes of each cross beam of the column sheet is (+0.25 mm), and the accumulated error between the connecting holes of the full length of the column sheet is (+3 mm).

The bending error of column sheet is less than L/1000 and less than 15 mm.

The ultimate deviation of the total height of the column sheet is (+2 mm).

The limit deviation of column width is (+2 mm).

The manufacturing length deviation of the column is (+2 mm).

The ultimate deviation of the beam length is (+1 mm).

The bending degree of the beam is less than L/1000 and less than 3 mm.

6. Installation Accuracy of Shelf

The height deviation of the same layer beam is (+5 mm).

The height of the cross beam on one side of the stacker should not be lower than that on the other side, and its height difference should be less than - 2 ~ + 4mm.

The vertical deviation between the column and the installation ground is less than L/1000mm and less than 15 mm.

The limit deviation of the center distance between the bottom of the adjacent rack piece column is (+2 mm).

The dislocation of the same rack piece in the same roadway should be less than 5 mm.

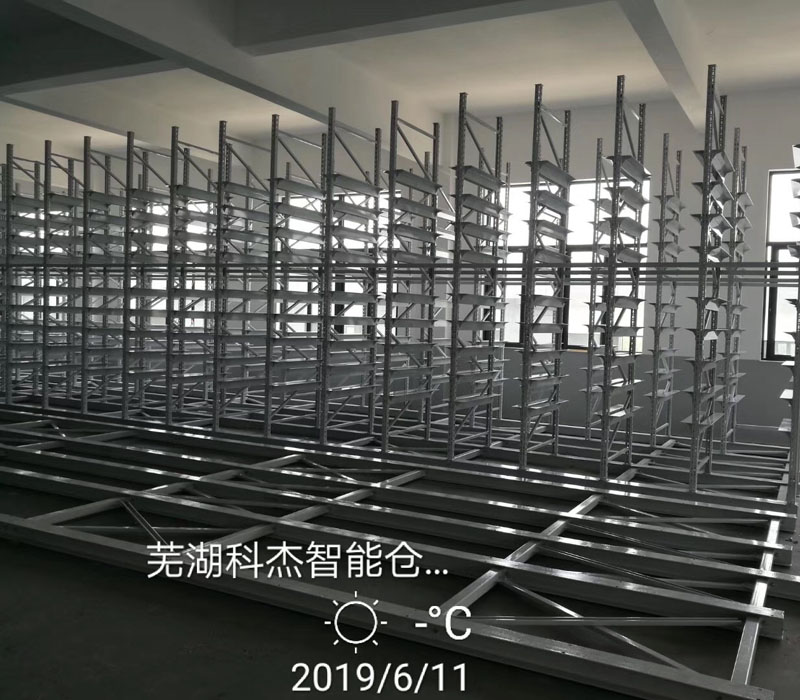

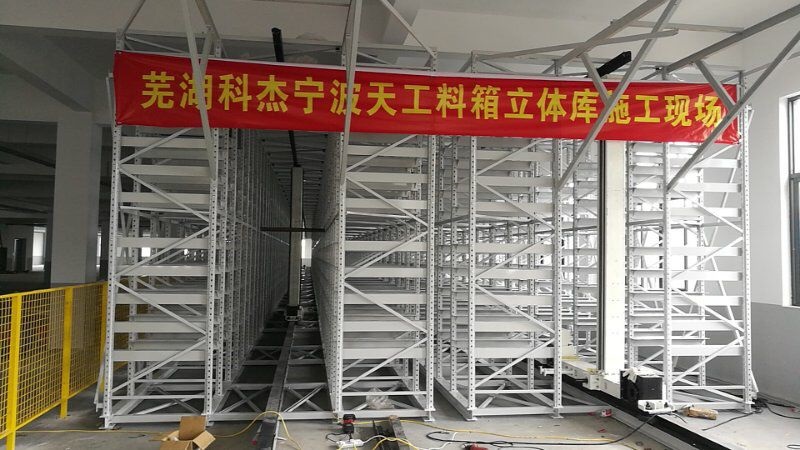

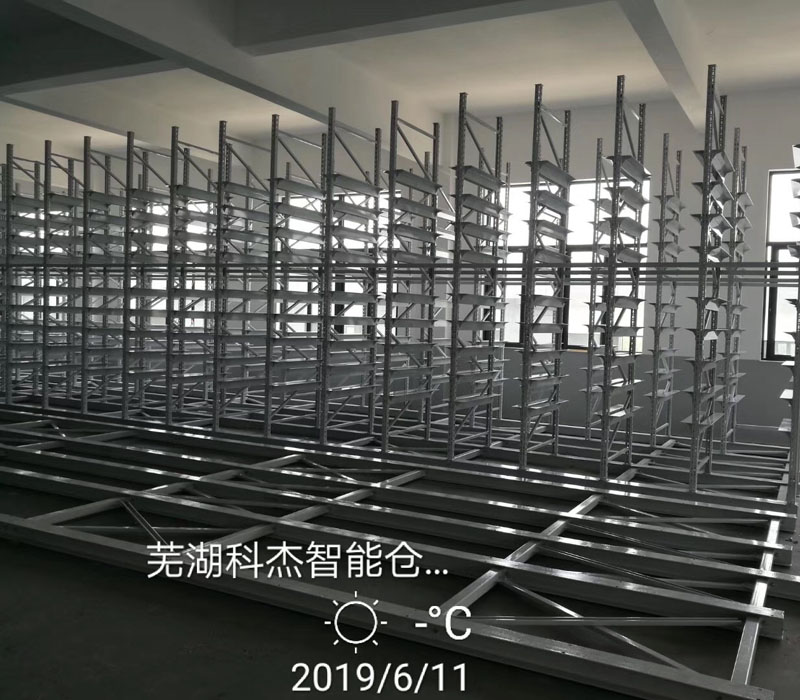

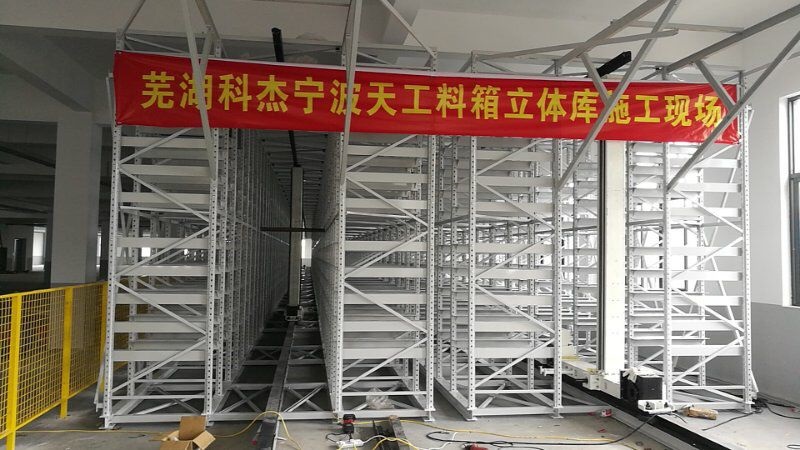

7.Live pictures

Provide intelligent warehousing logistics equipment solutions business.

Provide intelligent warehousing logistics equipment solutions business. Continue to explore the possibility of user experience

Continue to explore the possibility of user experience Our service is not a slogan, a concept or an advertisement. Our service is serious.

Our service is not a slogan, a concept or an advertisement. Our service is serious. You are welcome to call for information or appointment.

You are welcome to call for information or appointment.