First, the basic introduction of the shelf of the automated three-dimensional warehouse

Automated three-dimensional warehouse is a new concept in logistics warehousing. The use of stereoscopic warehouse equipment can realize the rationalization of high-level warehouse, automation of access, and simplification of operation. Automated stereoscopic warehouse is a form of high technology level at present. The main body of the automated warehouse is composed of shelves, roadway stacking cranes, workbenches in (out) warehouses, automatic transportation in (out) and operation control systems. The rack is a building or structure of steel or reinforced concrete structure. The rack is a space of standard size. The roadway stacking crane travels through the roadway between the racks to complete the work of stock and pick-up. Computer and bar code technology are used in management.

Second, Shelf Components of Automated Stereo Warehouse

1. Shelf: Steel structure for storing goods. There are mainly two basic forms: welded shelf and combined shelf.

2. Pallets (containers): Appliances used to carry goods, also known as station appliances.

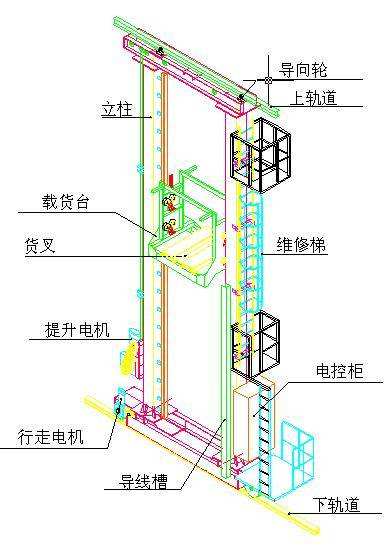

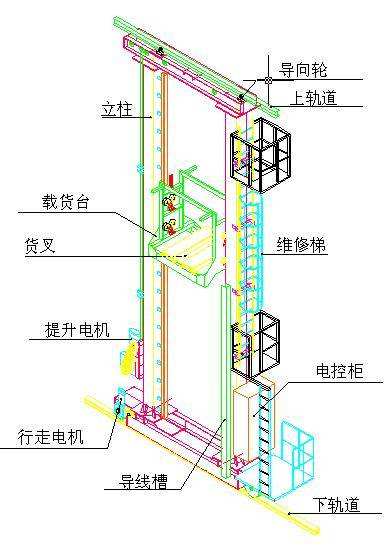

3. Roadway stacker: equipment for automatic access to goods. According to the structure form, it can be divided into two basic forms: single column and double column; according to the service mode, it can be divided into three basic forms: straight road, bend road and transfer vehicle.

4. Conveyor system: the main peripheral equipment of the three-dimensional storehouse, responsible for transporting goods to or from the stacker to remove goods. There are many kinds of conveyors, such as roller conveyor, chain conveyor, elevator, distributor, elevator, belt conveyor and so on.

5. AGV system: auto-steering car. According to its guiding mode, it can be divided into inductive guiding car and laser guiding car.

6. Automatic control system: the automatic control system that drives the equipment of the automatic stereo library system. Fieldbus is the main mode of control.

7. Storage information management system: also known as central computer management system. It is the core of the fully automated three-dimensional library system. Typical automated three-dimensional database systems use large database systems (such as ORACLE, SYBASE, etc.) to build a typical client/server system, which can be networked or integrated with other systems (such as ERP systems).

Third, the advantages of shelf system in automated warehouse

1. Save the area of the warehouse and make full use of the space of the warehouse. Because the automated warehouse uses adopt the assembly of large warehouse shelves and the automated management technology make the goods easy to find, the construction of automated warehouses occupies less space than traditional warehouses, but the space utilization rate is large. In developed countries, improving the utilization rate of space has become an important assessment index for the rationality and advancement of the system. In today's advocacy of energy conservation and environmental protection, automated three-dimensional warehouse has a good effect in saving occupied land resources, but also will make the future development of warehousing a major trend.

2. Automation management improves the management level of warehouse. Automated warehouse uses use uses computer to manage goods information accurately and correctly, which reduces the errors that may occur in the storage of goods and improves work efficiency. At the same time, the three-dimensional automated warehouse realizes the motorization in the delivery of goods into and out of the warehouse, and the handling work is safe and reliable, which reduces the damage rate of goods. It can also make some goods with special requirements for the environment have a good preservation environment through special design, such as toxic and explosive goods, and also reduces the harm that people may suffer when handling goods.

3. Automated three-dimensional warehouse can form an advanced production chain and promote the progress of productivity. Professionals pointed out that, due to the high efficiency of storage, the automated warehouse can effectively connect the production links outside the warehouse and form an automated logistics system in the storage, thus forming a planned and arranged production chain, which greatly improves the production capacity.

Provide intelligent warehousing logistics equipment solutions business.

Provide intelligent warehousing logistics equipment solutions business. Continue to explore the possibility of user experience

Continue to explore the possibility of user experience Our service is not a slogan, a concept or an advertisement. Our service is serious.

Our service is not a slogan, a concept or an advertisement. Our service is serious. You are welcome to call for information or appointment.

You are welcome to call for information or appointment.