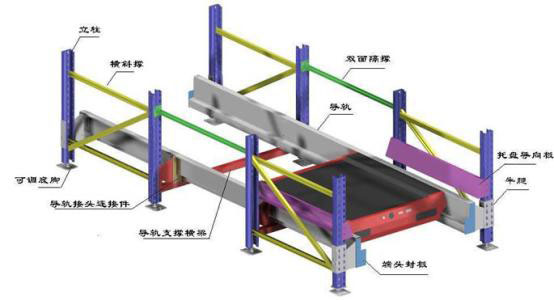

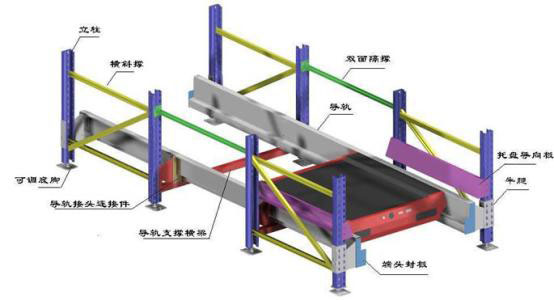

With the development of modular logistics concept and the acceleration of logistics standardization construction, a new high density and efficient storage mode brings new choices. This is an automated shuttle warehouse system based on unit. The shuttle shelf system is composed of shuttle trolley and track through shelf, which can realize dense storage of materials and increase the area utilization ratio of the three-dimensional warehouse to 90%.

The automatic high density storage system is composed of stacker, warehouse management system and shuttle shelf system. This new automatic shuttle warehouse can reduce investment, improve investment efficiency, and maximize the storage density and storage efficiency of the automated warehouse. Stacker + shuttle board can realize the intensive storage of pallet goods on the storage shelf, and through WMS/WCS control system, the shuttle board, stacker, conveyor and other equipment can be fully automated, which not only improves the storage density of warehouse, but also saves the passage and auxiliary space of forklift truck storage in the past, but also greatly reduces the labor cost. Greatly meet the customer's requirements for high-density storage of goods!

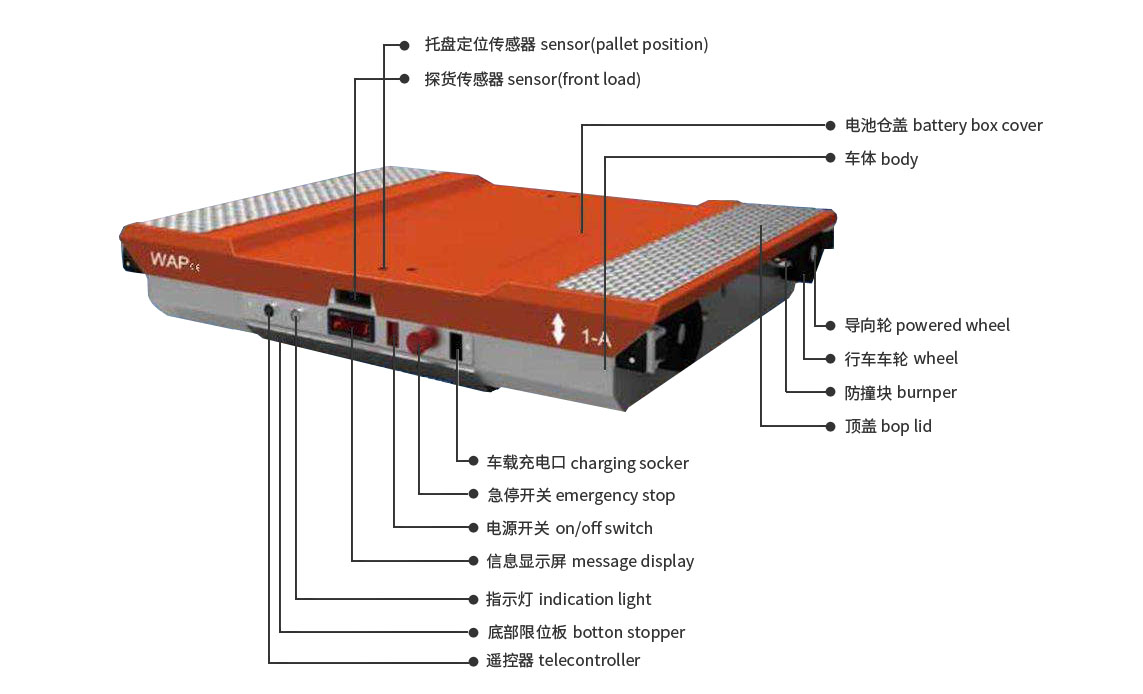

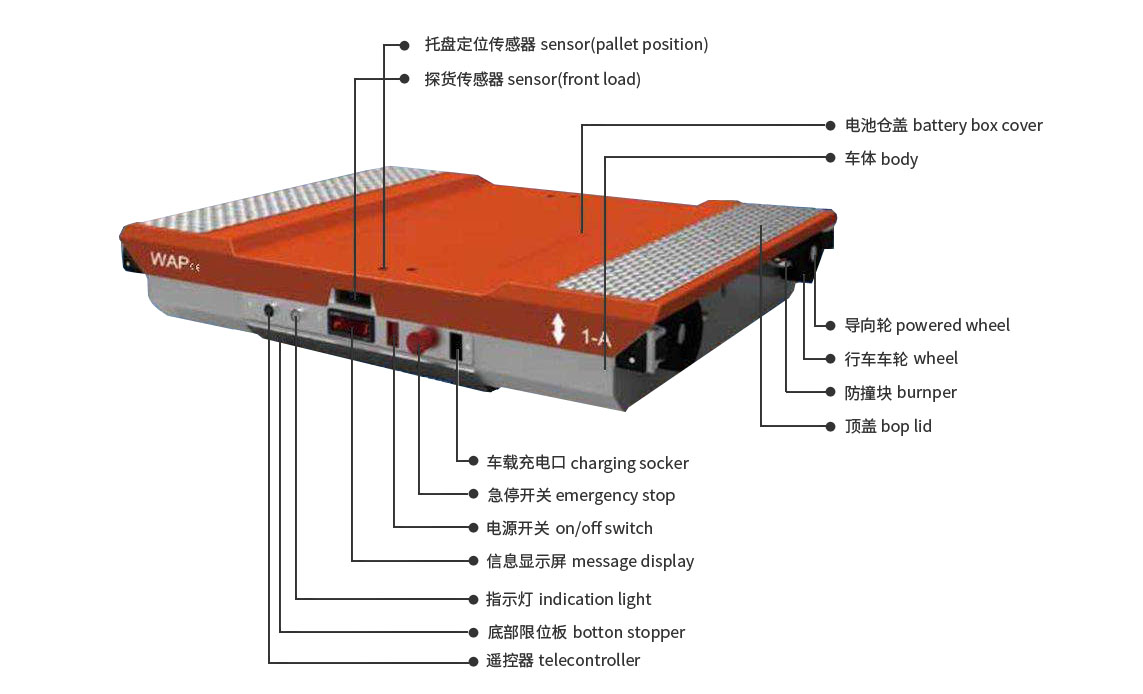

Shuttle board is an automatic pallet handling equipment used in dense storage stereo warehouse. It can maximize the space utilization of warehouse. It has flexible operation mode and cooperates with forklift truck to realize semi-automatic operation of warehouse. Because the use of through-shelf eliminates the working roadway, it can increase the utilization rate of warehouse space to more than 90%, realize the warehouse goods intensive storage, and greatly improve the investment efficiency.

Provide intelligent warehousing logistics equipment solutions business.

Provide intelligent warehousing logistics equipment solutions business. Continue to explore the possibility of user experience

Continue to explore the possibility of user experience Our service is not a slogan, a concept or an advertisement. Our service is serious.

Our service is not a slogan, a concept or an advertisement. Our service is serious. You are welcome to call for information or appointment.

You are welcome to call for information or appointment.