First, introduction of shuttle type stereoscopic warehouse.

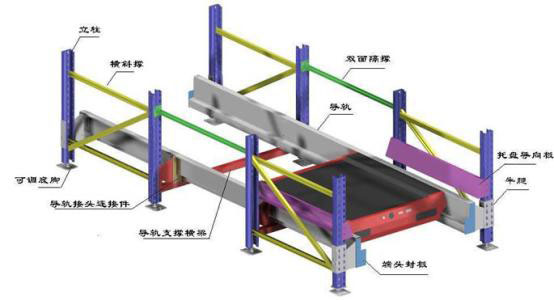

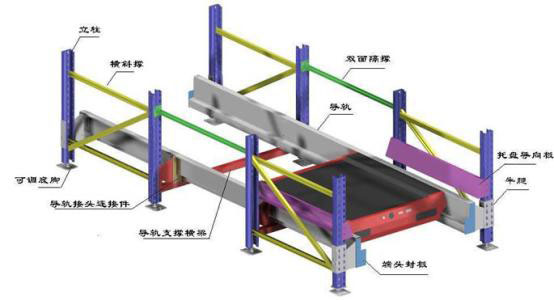

The shuttle warehouse system is evolved from the through-type shelf system, but the forklift truck does not need to drive into the inside of the shelf. It overcomes the shortcomings of the slow access speed of the through-type shelf and the poor stability of the shelf system, and realizes the remote control automation of the access. The outer tray goods are transported back by forklift truck, and the inner tray goods are stored and stored by shuttle-board trolley. In other words, when the goods are in stock, the forklift truck puts the tray goods into the front part of a certain layer of guideway in the shelf area. The tray goods are transported to the depth of depth by the shuttle-board trolley which is in the layer by wireless remote control. The pallet cargo in the bottom of the rack is moved to the port of the guide rail and the pallet is removed by the fork truck. This kind of shelf system is characterized by high storage space utilization, stable and reliable system, can achieve semi-automation, suitable for the storage of large quantities of small varieties of goods, such as food, beverage, refrigeration and other industries, shuttle boards can choose six-dimensional self-developed shuttle boards or imported shuttle boards. The connection between different areas of the shuttle board rack can also be carried out by the sub-car and the mother car, and the peripheral can also be carried out by the elevator or the stacker, thus building a higher degree of automation of high-density storage system.

Second, the characteristics of shuttle type stereoscopic warehouse

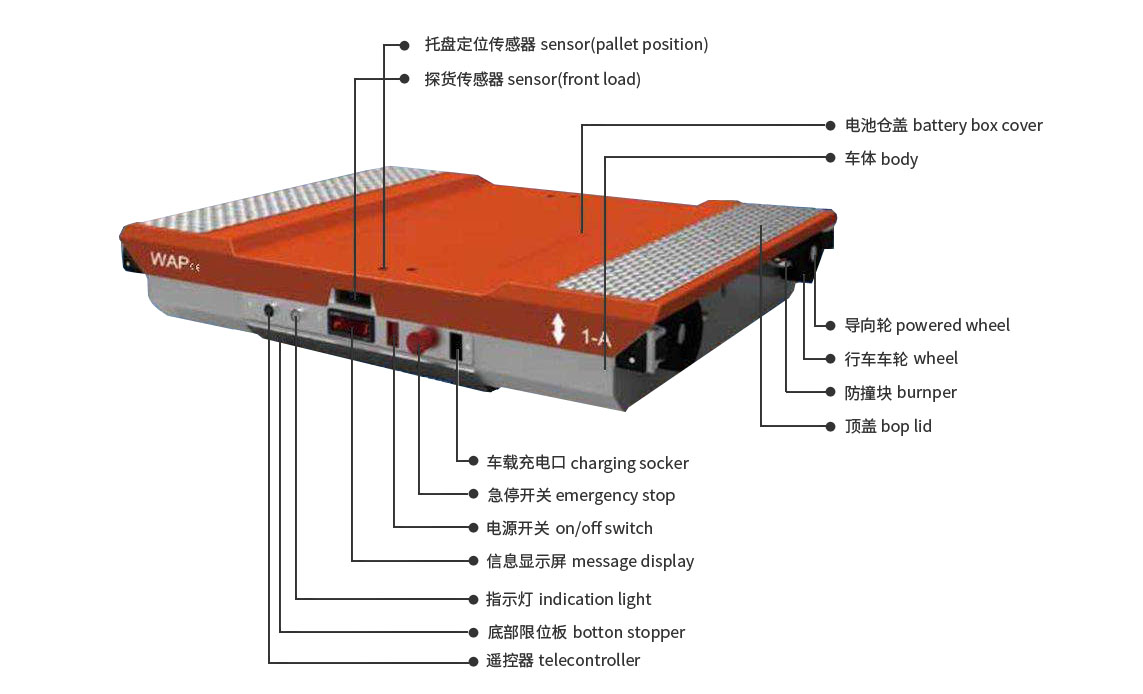

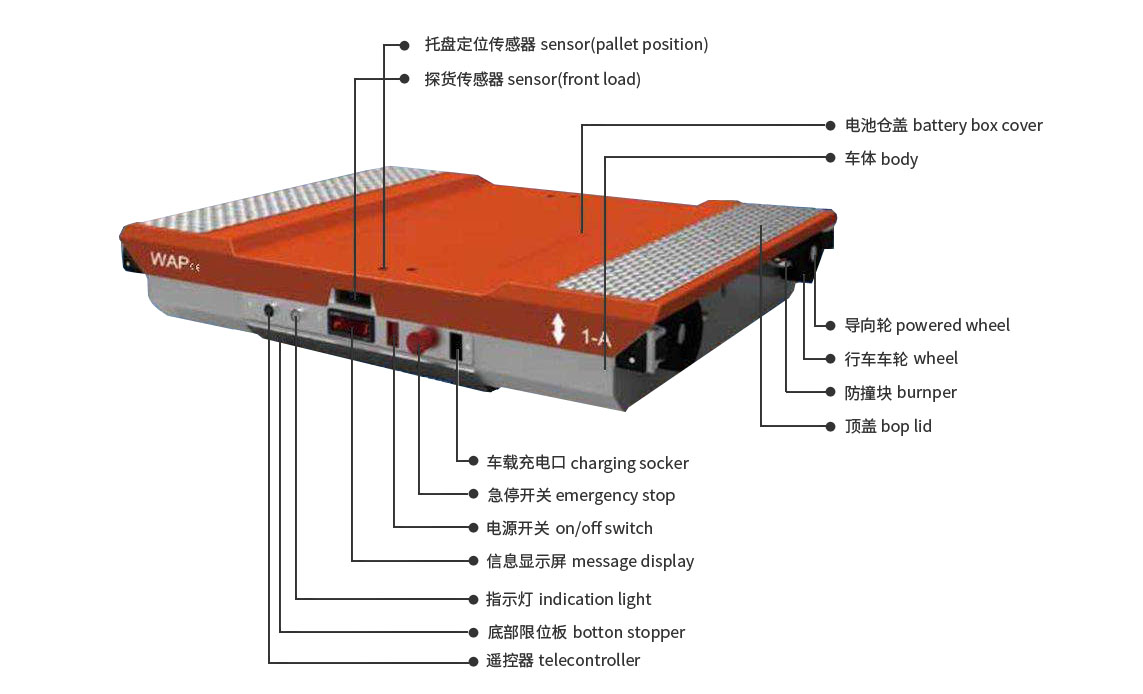

The 1. is composed of three parts: Shuttle rack, battery driven shuttle car and forklift truck.

2.貨架的結(jié)構(gòu)更合理、穩(wěn)定,抗地震安全性能大大高于駛?cè)胧截浖埽?br style="font-family: "Microsoft Yahei", Arial, Helvetica, sans-serif; box-sizing: border-box; text-size-adjust: none;"/>3.跟駛?cè)胧截浖芟啾龋┧筌?chē)貨架可設(shè)計(jì)的深度更大且密集;

4.叉車(chē)類(lèi)型的選擇多;

5.實(shí)現(xiàn)駛?cè)胧截浖軣o(wú)需駛?cè)?進(jìn)出貨效率高,大大節(jié)省空間及人力成本。

第三、穿梭式立體倉(cāng)庫(kù)產(chǎn)品優(yōu)勢(shì)

1. 自由選擇貨物批量進(jìn)出次序

2. 可選自動(dòng)功能多,操作簡(jiǎn)便

3. 單個(gè)遙控器可分別控制多臺(tái)穿梭車(chē)

4. 實(shí)時(shí)雙向遙控,可監(jiān)控多種穿梭車(chē)狀態(tài)—如電機(jī)溫度、電池電量、報(bào)警內(nèi)容等

5. 托盤(pán)間距可設(shè)定、托盤(pán)深度可變、可自動(dòng)統(tǒng)計(jì)托盤(pán)并理貨

6. 結(jié)構(gòu)設(shè)計(jì)更精準(zhǔn),確保高層存取流暢,實(shí)現(xiàn)托盤(pán)貨物最高密集度存放,顯著減少庫(kù)房建設(shè)費(fèi)用

7. 載重范圍廣,安全可靠

8. 可靠的安全防護(hù)設(shè)計(jì):防地震、防碰撞、防物件損傷

9. 智能預(yù)警模塊設(shè)計(jì),自動(dòng)實(shí)現(xiàn)常見(jiàn)故障自我排除和危險(xiǎn)作環(huán)境預(yù)警,使倉(cāng)儲(chǔ)系統(tǒng)工作穩(wěn)定性極佳

第四、穿梭式立體倉(cāng)庫(kù)設(shè)備好處

1.多量少樣:食品、飲品、化工、煙草等單品種批量大,品項(xiàng)相對(duì)單一的行業(yè)

2.冷庫(kù)作業(yè):減少低溫作業(yè)時(shí)間,提高工作效率和作業(yè)安全性

3.期限管理:對(duì)物品批次有嚴(yán)格要求,需要先進(jìn)先出作業(yè)管理的倉(cāng)庫(kù)

4.增加庫(kù)容:存儲(chǔ)空間有限,需要最大化利用空間的倉(cāng)庫(kù)

第五、穿梭式立體倉(cāng)庫(kù)安裝現(xiàn)場(chǎng)

1.科杰安裝人員在客戶工廠安裝動(dòng)力電池立體倉(cāng)庫(kù),物流輸送線現(xiàn)場(chǎng),安全操作并且安裝人員進(jìn)入現(xiàn)場(chǎng)前經(jīng)過(guò)嚴(yán)格訓(xùn)練

2.建立安全管理與安全組織

3.制定施工安全措施

4.安排安全管理人員進(jìn)行安全管理與安全監(jiān)護(hù)。

Provide intelligent warehousing logistics equipment solutions business.

Provide intelligent warehousing logistics equipment solutions business. Continue to explore the possibility of user experience

Continue to explore the possibility of user experience Our service is not a slogan, a concept or an advertisement. Our service is serious.

Our service is not a slogan, a concept or an advertisement. Our service is serious. You are welcome to call for information or appointment.

You are welcome to call for information or appointment.