Stereoscopic warehouse stacker is driven by walking motor through driving axle to do horizontal walking, vertical lifting by hoist, and telescopic movement by fork on cargo platform. Through radio and television identification and conversion of optical communication signals, computer control can be realized. Manual and moving control of stacker control cabinet can also be realized. The application of warehouse stacker greatly shortens the buffer distance between start and stop of the stacker, and improves the operation efficiency of the stacker.

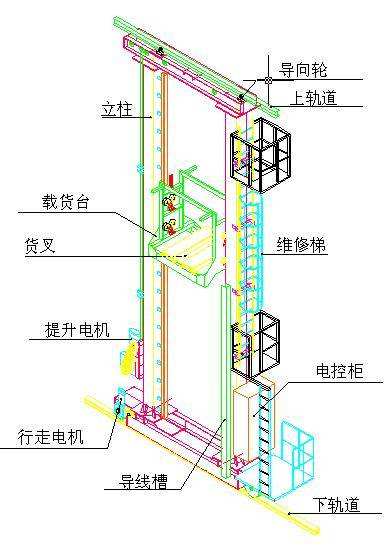

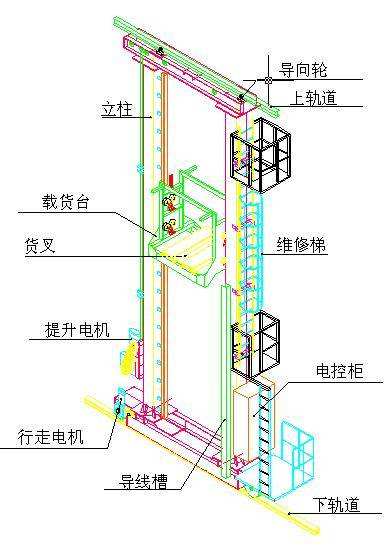

The stacker is mainly composed of lower crossbeam, loading platform, fork mechanism, column, upper crossbeam, horizontal operation mechanism, lifting mechanism, electronic control cabinet, safety protection device and electrical control system.

The electronic control system of stereoscopic warehouse has the functions of sound and light alarm for fault detection and fault status and elimination of sound and light alarm. The combined core storage vertical storehouse is used to store groups of sand cores and empty pallets, which plays a role in regulating the balance between supply and demand of sand cores between core-making and moulding departments.

control model

Three-dimensional warehouse stacker work has four control modes: maintenance, manual, single machine automation and on-line automation.

Maintenance mode

The operator boards the plane and controls directly the movement of the stacker in and out of the warehouse or the expansion and retraction of the fork through the HMI touch screen operation menu. At this time, the working state of the stacker is stop mode (similar to point movement), during which the operation or stop, high and low speed switching is completely controlled by the operator. This mode is usually used in equipment debugging or maintenance.

Manual mode

Operators boarded the aircraft and directly controlled the movement of the stacker's advance and retreat, lifting or fork through the HMI touch screen operation menu. At this time, the working state of the stacker is semi-automatic mode, that is, the three-dimensional movement in all directions is started manually, and automatically aligned and stopped. Used in equipment debugging or general failure, artificial random access operation.

Single machine automatic mode

Operators input operation commands (multiple operation commands can be input at a time) through the HMI touch screen operation menu in the stacker operation panel (or the ground operation panel when there is a ground operation station). After the stacker automatically completes the operation, it returns to its original position and waits for the next batch of instructions.

On-line (on-line) automatic mode

The stacker receives the operation instructions from the upper computer through the infrared communicator, completes one operation automatically, and waits for the next one in situ. The operation process and completion are fed back to the host computer in real time.

Positioning method

Stackers generally use light-shielded photoelectric detection and positioning in horizontal and vertical direction. Now more advanced rotary encoders, laser rangefinders or bar code bands and scanners are used to achieve closed-loop speed regulation and accurate positioning. Fork expansion direction is positioned by proximity switch.

The Important Means of Stereoscopic Warehouse Stacker to Promote Enterprise Profit

In the future, with the expansion of the scale of Chinese enterprises, as well as the increasing awareness of the importance of land and the rational use of this scarce resource, the automated three-dimensional warehouse with the advantages of saving land resources and improving the management level of enterprises will be more widely used. Enterprises must carry out comprehensive innovation and product upgrading in order to seize the opportunities given by the times.

Provide intelligent warehousing logistics equipment solutions business.

Provide intelligent warehousing logistics equipment solutions business. Continue to explore the possibility of user experience

Continue to explore the possibility of user experience Our service is not a slogan, a concept or an advertisement. Our service is serious.

Our service is not a slogan, a concept or an advertisement. Our service is serious. You are welcome to call for information or appointment.

You are welcome to call for information or appointment.