1. Overview of Shuttle Solid Library

The planning and design process of shuttle solid warehouse is complex and rigorous. It not only meets the design requirements of strength, stiffness and stability of the shelf structure of shuttle solid warehouse, but also ensures the performance and reliability of the configuration equipment of the soft control system, and reasonably evaluates the operation efficiency, system flow optimization and the realization of its control function of Shuttle Solid Warehouse system. The following Kojie Intelligent Warehousing Equipment tells you about the types and characteristics of shuttle stereo warehouse:

2. Classification of shuttle stereo library

(1) Ordinary Shuttle Solid Library

The semi-automatic three-dimensional warehouse system consisting of shuttle rack system and forklift truck and other multi-dimensional storage and handling equipment mainly relies on manual forklift truck storage operation to realize warehousing operation of goods in shuttle shelf warehouse area on the working surface (i.e. the coplanar of forklift operation area and shuttle shelf storage area), while in shuttle shelf, it relies on two-way straight-line shuttle. Vehicle realizes automatic operation of goods storage and handling. Because of its moderate investment cost, basically does not change the mainstream means and process of operation outside the original storage area, and can improve the storage density and operation efficiency of storage area, it has become one of the mainstream equipment forms in the market.

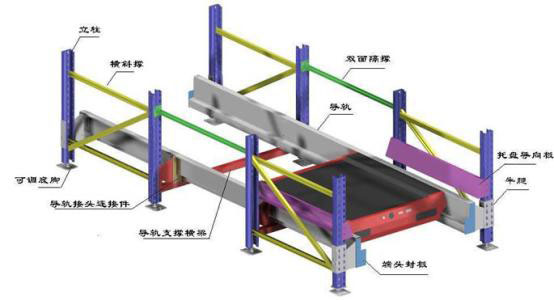

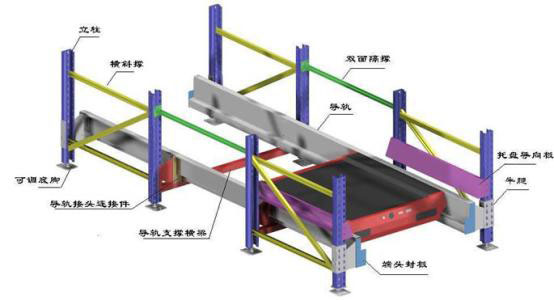

(2) Shuttle-type stereo library for mother and child

The system consists of shuttle shelf system, shuttle mother car and lifting, handling and storage system. By strengthening the functionality of shuttle shelf structure, the shuttle subcar traveling in two-way straight line is combined with the mother car traveling in two-way straight line to realize seamless docking and displacement of flat warehouse unit items, while the hoist is used to realize the replacement of shuttle subcar or storage items, so as to realize the three-dimensional dynamic storage management of storage unit in the whole storage area, which is shuttle warehouse construction. At present, the technical grafting and extension is one of the mainstream warehousing management forms recommended by shuttle design and manufacture enterprises, shelf enterprises or system integrators.

(3) Stacking shuttle type solid warehouse

Using shuttle rack system and automated laneway stacker handling storage system, relying on the automated laneway stacker handling storage system, shuttle rack storage area can be freely divided into several working areas and channels, which greatly improves and balances the storage and handling efficiency of the working area and storage area. It is the construction of traditional automated vertical storage system and ordinary shuttle three-dimensional storage. Structural extension is one of the main warehouse management forms recommended by system integrators to customers.

(4) Intelligent Shuttle Solid Library

It adopts shuttle shelf system, intelligent shuttle system and lifting, handling and storage system. Intelligent shuttle system realizes four-way logistics operation of the same level roadway by shuttle truck body according to operation instructions. It can realize storage scheduling and management of arbitrary storage space at the same level. Combined with hoist, intelligent shuttle bicycle or leveling operation of storage items can be realized, so as to realize three-dimensional dynamic storage management of storage unit in the whole storage area. It is shuttle-type warehouse construction and management. The upgrading and upgrading of the transformation is also one of the ideal logistics forms of intelligent shuttle intensive storage.

Provide intelligent warehousing logistics equipment solutions business.

Provide intelligent warehousing logistics equipment solutions business. Continue to explore the possibility of user experience

Continue to explore the possibility of user experience Our service is not a slogan, a concept or an advertisement. Our service is serious.

Our service is not a slogan, a concept or an advertisement. Our service is serious. You are welcome to call for information or appointment.

You are welcome to call for information or appointment.