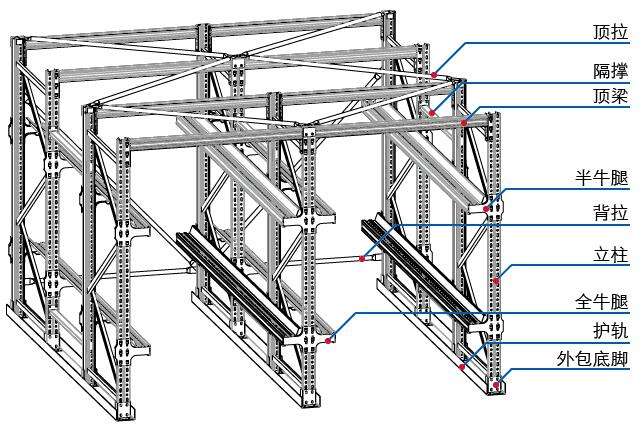

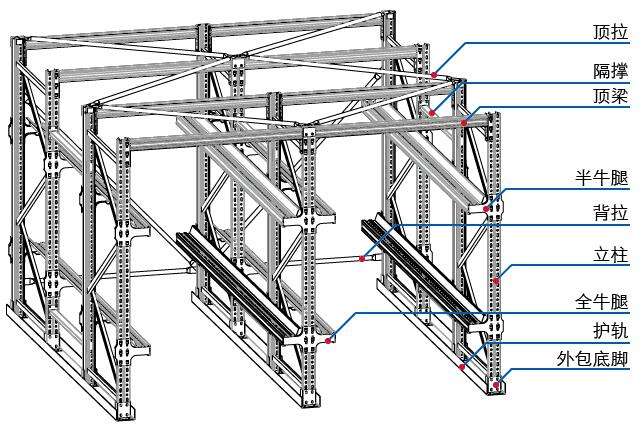

The through shelf is also known as the corridor shelf or the driving shelf. The through shelf adopts pallet access mode, which is suitable for the storage of goods of small variety and large batch. In addition to the cargo space close to the passage, as forklift trucks need to enter the shelf to access cargo, it is usually recommended that the single-side pickup should not exceed 7 cargo depth. In order to improve the speed of forklift truck operation, the guide track can be selected according to the actual needs. Compared with the cargo shelf, the utilization rate of storage space of the through shelf (driving shelf) can be increased by more than 30%. The through shelf (driving shelf) is widely used in cold storage and food and tobacco industry.

1. Characteristic of through shelf

1. On the supporting guide rail, the pallets are stored in the depth direction, one after the other, which makes the pallets stored in the depth direction.

High-density storage is possible.

2. Goods are accessed from the same side of the shelf, first stored, then taken, and then stored. Balanced weight and forward forklift trucks can easily drive into the shelf to access goods without occupying multiple channels.

3. This kind of shelf is suitable for storing large quantities and few varieties of through-type shelves (driving shelves) with integral stamping/rolling technology. It has strong bearing capacity and beautiful appearance.

The total depth of the shelf in the wall area is generally better controlled within 5 pallet depths. The total depth of the shelf in the middle area is generally better controlled within 10 pallet depths, so as to improve the efficiency and reliability of forklift truck access.

The stability of through-type shelf system is weaker in all kinds of shelves, so the shelf should not be too high, generally within 10 meters. In addition, the system also needs to install a pulling device. This system has dense shelf arrangement and high space utilization. It is suitable for storing a small variety of similar goods in large quantities. Goods can be stored and taken out from the same side or from one side to the other.

1. Driving-in shelves are also called corridor shelves or through shelves.

2. Forklift trucks can be driven into the laneway to store pallets.

3. Access mode is FIFO or FIFO: from the same side in and out for FIFO, from one side in and out for FIFO.

4. It can greatly improve the utilization rate of space.

2. Daily maintenance of through shelves

Daily maintenance and maintenance of shelves also reflects the top priority of a shelf factory service. TMCC regularly maintains and maintains customers'high shelves to ensure efficient storage and safe use of shelves.

(1) Clean and timely discover the mechanical deformation of shelves through external force collision and timely replace the safe and stable shelf parts. In line with the first safety criterion, in the cleaning process, timely discovery of potential safety hazards, timely handling, ensure safe and efficient storage.

(2) Professional horizontal stereo positioning tools are used to correct the shelf condition, and then effectively correct it to ensure the shelf bearing capacity and safety.

(3) Strictly enforce the rules of safe use, no overload, over-line location, over-storage density, to ensure the safety performance in the storage process.

(4) The maintenance cycle is one year.

(5) Maintenance includes the routine contents of fastener tightness measurement, column vertical measurement, damaged parts measurement, etc. If the column is bent or broken, it needs to be measured as a whole. Maintain the system according to the measured data.

Provide intelligent warehousing logistics equipment solutions business.

Provide intelligent warehousing logistics equipment solutions business. Continue to explore the possibility of user experience

Continue to explore the possibility of user experience Our service is not a slogan, a concept or an advertisement. Our service is serious.

Our service is not a slogan, a concept or an advertisement. Our service is serious. You are welcome to call for information or appointment.

You are welcome to call for information or appointment.