Automated Stereo Warehouse (AS/RS/System) is a warehouse that can realize automatic storage and computer management of goods in container unit. Automated Stereo Warehouse is composed of several systems, including the main shelf system, as well as stacker system, conveyor system, pallet and material, and control system.

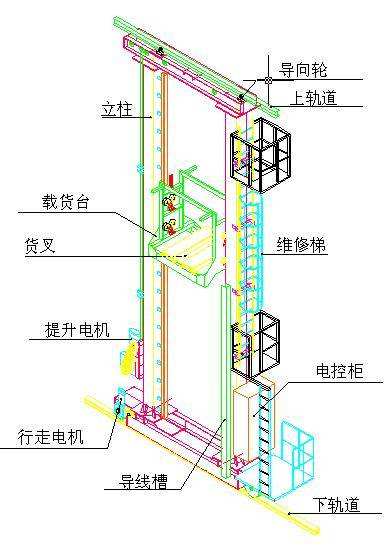

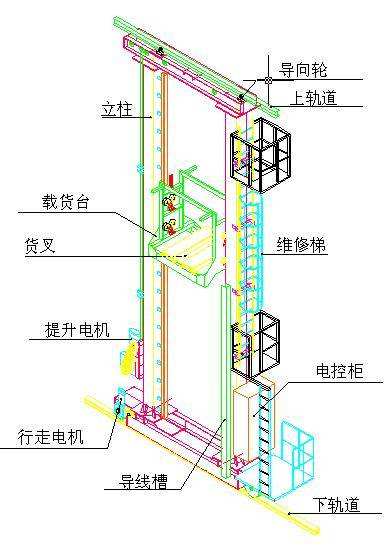

Site Map of Automated Stereoscopic Warehouse:

Automated warehouse is widely used in machinery manufacturing, electronics industry, chemical industry and manufacturing industry, printing and publishing industry, textile industry, securities industry, food industry, transportation services and so on. Our company undertakes the overall design of automated warehouse, equipment design, manufacturing, installation, commissioning, after-sales maintenance and other services, providing turnkey engineering.

Automated three-dimensional warehouse is a comprehensive science and technology project of material handling and warehousing science. It takes high-rise three-dimensional shelves as its main symbol, takes complete sets of advanced handling equipment as its basis, and advanced computer control technology as its main means, and efficiently uses space, time and manpower to carry out warehouse entry and exit processing. The application of automated warehouse technology in the field of goods circulation can greatly improve the efficiency of goods circulation and reduce the labor intensity of staff. It has been widely used in many large and medium-sized enterprises.

Explain

Automated three-dimensional warehouse is a multi-storey elevated warehouse system for goods storage. It is mainly composed of high-level shelves, Space-earth tracks, roadway stackers, storage and transportation equipment, automatic control and management system. Stackers and warehouse entry and exit equipments can automatically complete the operation of goods entering and leaving warehouses, automate the management of goods, and connect with the enterprise management system to realize the modernization of management. As an important automated three-dimensional warehouse, it is a multi-storey elevated warehouse system for storing goods, mainly consisting of high-level shelves, Space-earth tracks, and so on. Roadway stacker, storage and transportation equipment, automatic control and management system. Stackers and warehouse entry and exit equipment can automatically complete the operation of goods in and out of the warehouse under the computer management, automate the management of goods, and connect with the enterprise management system to realize the modernization of management, which is an important part of the enterprise's modernization management.

Tracked laneway stacker is the main machine in the complete set of equipment of stereoscopic warehouse, and it is a kind of lifting machine running on the track. It can carry out reciprocating movement in three-dimensional space (walking, lifting, bilateral expansion) according to a certain sequence combination, in order to complete the entry and exit of the loading unit or the selected goods into the warehouse industry. This product adopts double pillar structure. The automatic stacker adopts a batch of new technologies. In addressing technology, the laser range finder is small in size and light in weight, and its measuring accuracy reaches millimeter level. The stacker applies frequency conversion technology. According to the target requirements of the stacker operation, the speed of the converter is switched by PLC to achieve the purpose of speed regulation and accurate parking. Speed control requirements for high-speed operation, stable speed change and low-speed stop of stacker. Practical application shows that the scheme can precisely control motor torque, have good performance at low speed and wide speed range.

The control design of stacker is manual, semi-automatic and full-automatic. Full automatic control is sent by monitor

Operating orders and addresses are given to the stacker, and then the stacker responds. In operation, the monitor monitors the operation status of the stacker in real time. Manual and semi-automatic control is to set operation orders and addresses directly by operators on the stacker operation panel. In actual operation, automatic control is the main method, manual and semi-automatic control is the auxiliary means of maintenance and debugging.

Provide intelligent warehousing logistics equipment solutions business.

Provide intelligent warehousing logistics equipment solutions business. Continue to explore the possibility of user experience

Continue to explore the possibility of user experience Our service is not a slogan, a concept or an advertisement. Our service is serious.

Our service is not a slogan, a concept or an advertisement. Our service is serious. You are welcome to call for information or appointment.

You are welcome to call for information or appointment.