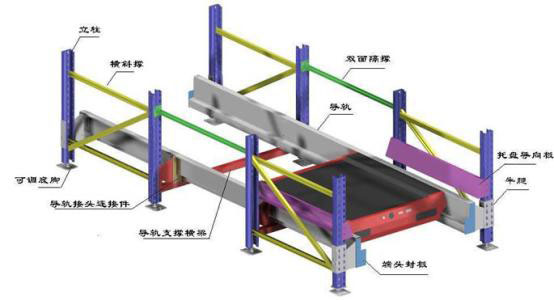

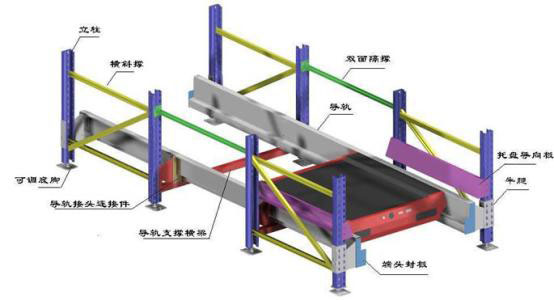

Shuttle rack is a high efficient and efficient high-density storage system.

Shuttle rack system is a high-density storage system composed of rack, shuttle trolley and forklift truck. This efficient storage mode brings new choices to improve the utilization of warehouse space.

Working Principle of Shuttle Shelf:

Inventory: Forklift trucks put the goods in the front of the rack roadway guide rail. The shuttle trolley operated by radio remote control can carry the pallet goods on the guide rail.

Delivery: When picking up goods, the shuttle trolley moves the pallet deep in the shelf to the front end of the shelf, and removes the pallet goods from the shelf by forklift truck.

Mobile trolley: The shuttle trolley can be placed in different roadways by forklift. Multiple roadways can share one shuttle trolley. The number of shuttle trucks is determined by comprehensive factors such as roadway depth, total cargo volume, shipment volume and frequency.

Shuttle shelf features:

· High utilization rate of warehouse

· First in first out or first in last out

· High efficiency

· Safety of use is much better than other shelves.

Shuttle shelf industry:

· Large quantities and few samples: food, beverage, chemical industry, tobacco and other industries with large quantities of single varieties and relatively single items

· Cold Storage Operation: Reduce Low Temperature Operation Time, Improve Working Efficiency and Safety

· Time limit management: Warehouse with strict requirements for batches of goods and first-in-first-out operation management

· Increasing Storage Capacity: Storage space is limited and warehouses need to maximize the use of space

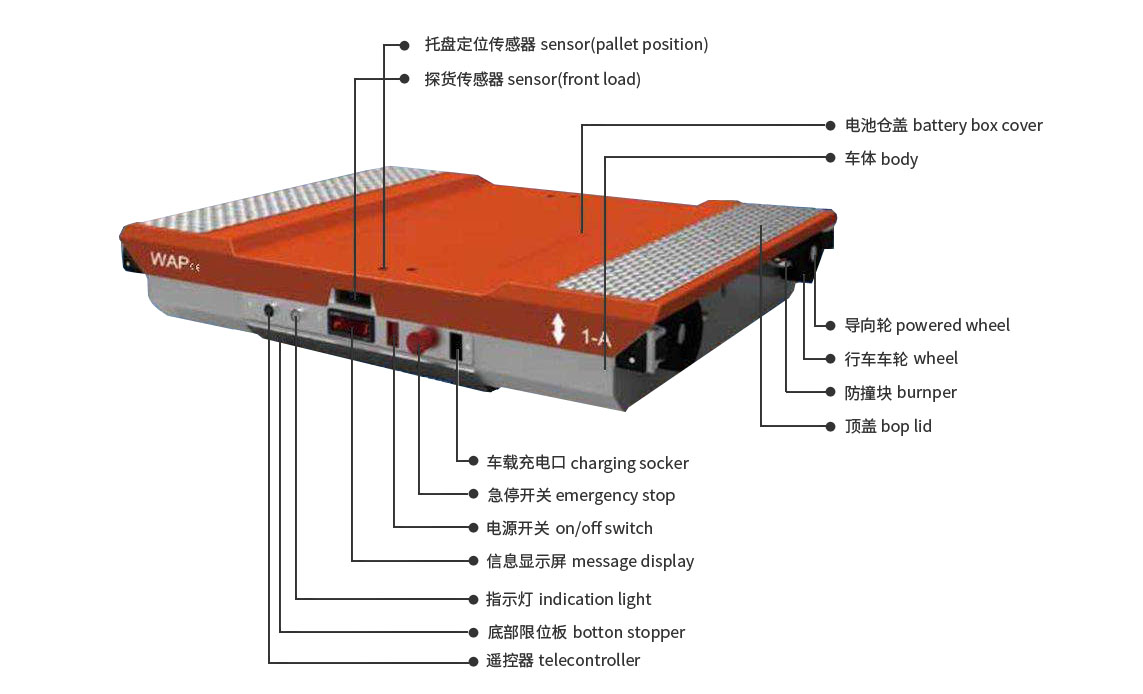

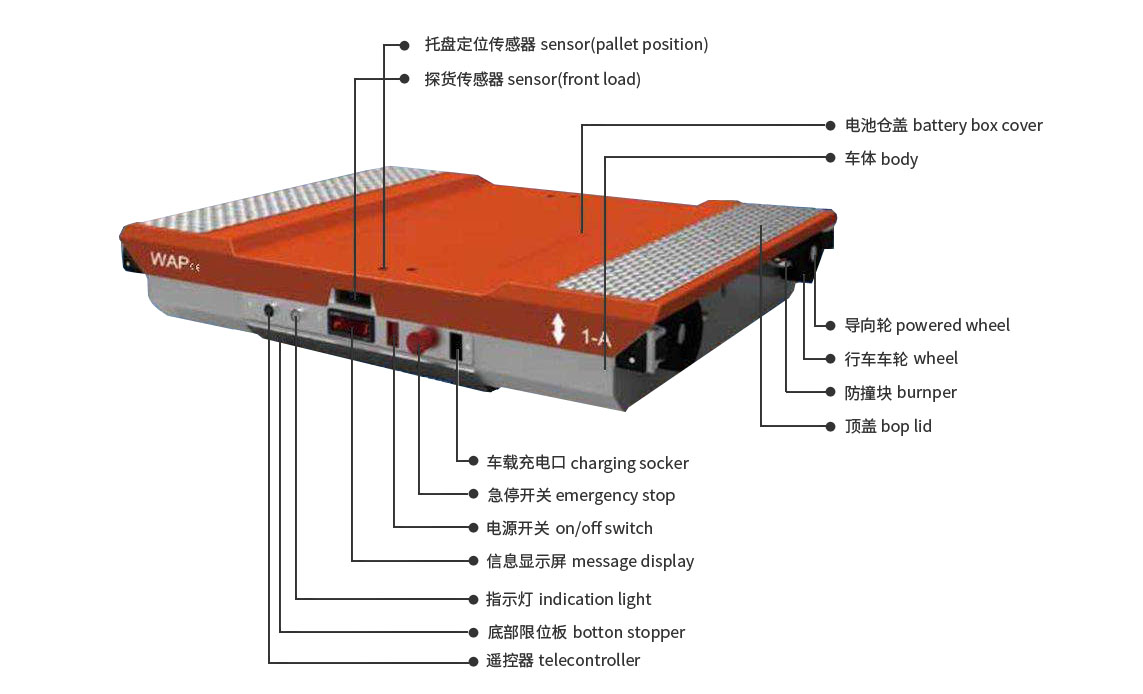

Instructions for the use of linear shuttle trucks at room temperature:

Technical parameters of shuttle shelves

Load: 1000-1500kg

Running speed: No-load 0.7-0.9 m/s

Running speed: full load 0.6-0.8 m/s

Power unit: lithium-manganese battery

Rated voltage: 26 Volts

Battery life: longer than 8 hours

Induction Range: Remote Controller Induction Range 50m

Provide intelligent warehousing logistics equipment solutions business.

Provide intelligent warehousing logistics equipment solutions business. Continue to explore the possibility of user experience

Continue to explore the possibility of user experience Our service is not a slogan, a concept or an advertisement. Our service is serious.

Our service is not a slogan, a concept or an advertisement. Our service is serious. You are welcome to call for information or appointment.

You are welcome to call for information or appointment.