First, introduction of shuttle warehouse

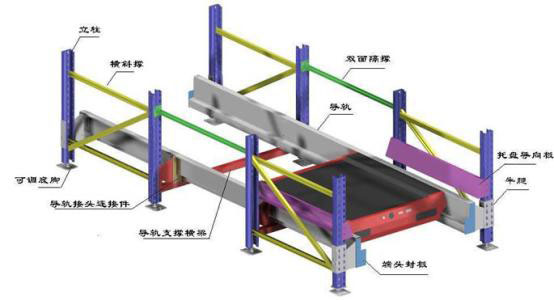

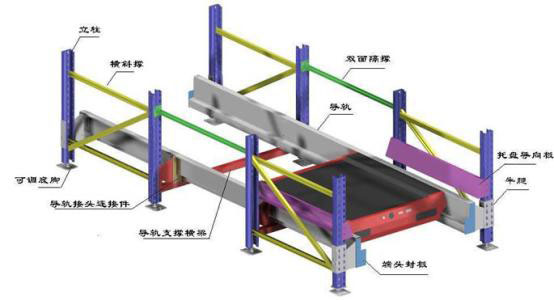

The shuttle warehouse system is evolved from the through-shelf system, but forklift truck does not need to drive into the inside of the shelf, which overcomes the shortcomings of slow access speed and poor stability of the shelf system, and realizes remote control automation of access. The outer pallet goods are reversed by forklift trucks, and the inner pallet goods are accessed and stored by shuttle trolley. That is to say, the pallet goods are placed by forklift trucks at the front end of a certain layer of guide rails in the shelf area when they are in stock. The pallet goods are transported to the longitudinal depth by the shuttle trolley located in the layer through wireless remote control. The pallet goods are moved to the port of the guide rails at the depth of the shelf before being taken out by remote control shuttle plate. The pallet is removed by forklift truck. This kind of shelf system is characterized by high utilization of storage space, stable and reliable system, semi-automation, suitable for the storage of large quantities of small varieties of goods, such as food, beverage, refrigeration and other industries, shuttle boards can choose six-dimensional self-developed shuttle boards or imported shuttle boards. The connection between different areas of shuttle board rack can also be carried out by the combination of subcar and mother car, and the peripheral can also be carried out by elevator or stacker, thus building a high-density storage system with a higher degree of automation.

Second, the characteristics of shuttle warehouse

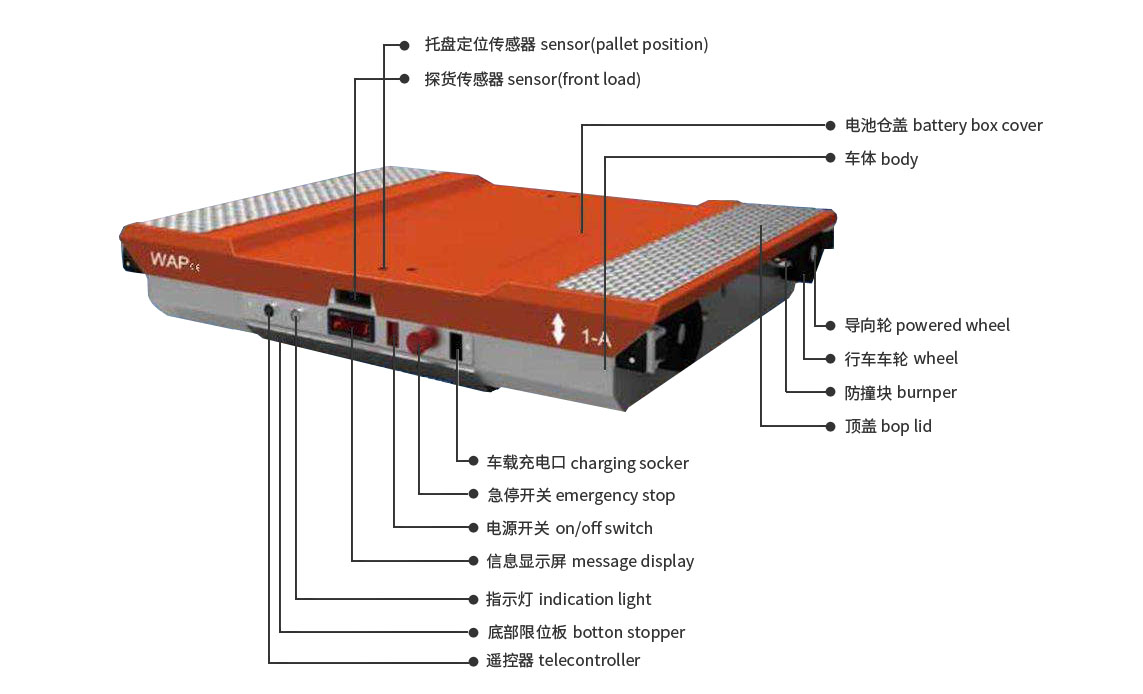

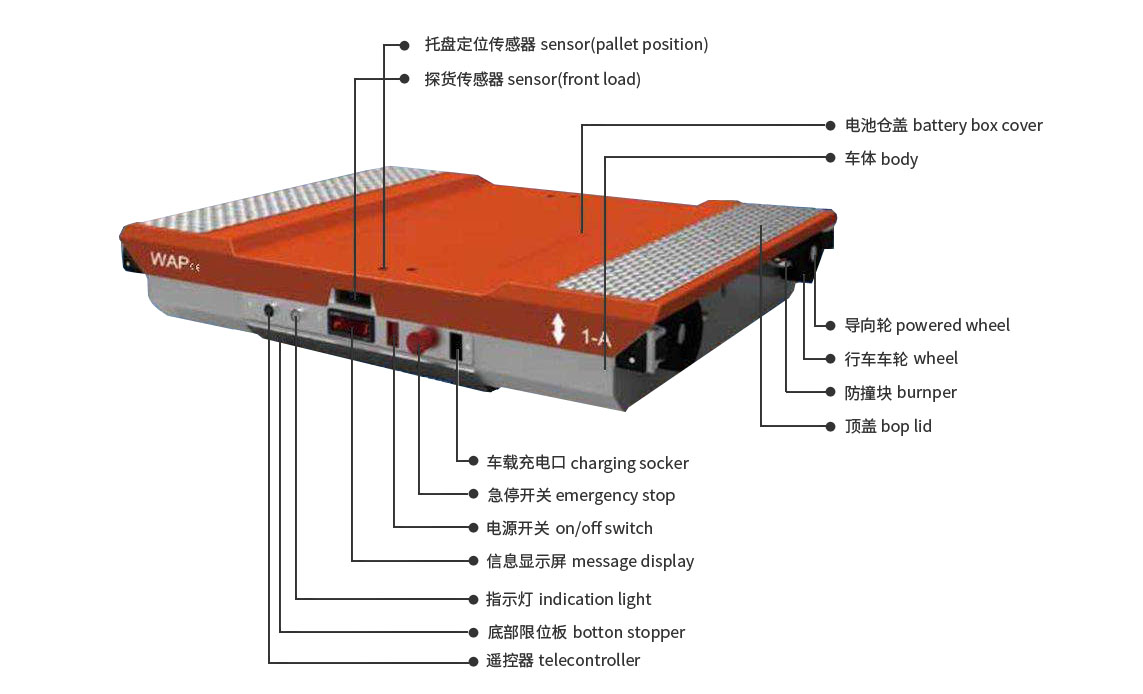

1. It consists of shuttle truck rack, battery-driven shuttle truck and forklift truck.

2. The structure of the shelf is more reasonable and stable, and the seismic safety performance of the shelf is much higher than that of the driving shelf.

3. Compared with the drive-in rack, the shuttle rack can be designed with greater depth and density.

4. There are many types of forklift trucks.

5. Realize that the drive-in shelf does not need to be driven in, and the efficiency of incoming and outgoing goods is high, which greatly saves space and manpower costs.

Third, the advantages of shuttle warehouse products

1. Free choice of the order of goods in and out in batches

2. Multiple optional automatic functions and easy operation

3. A single remote controller can control multiple shuttles separately.

4. Real-time bidirectional remote control, which can monitor various shuttle vehicle states, such as motor temperature, battery power, alarm content, etc.

5. Pallet spacing can be set, pallet depth can be changed, automatic statistics pallet and tally

6. Structural design is more precise to ensure the smooth access of high-rise buildings, realize the highest density of pallet goods storage, and significantly reduce the cost of warehouse construction.

7. Load range is wide, safe and reliable

8. Reliable Safety Protection Design: Earthquake-proof, Collision-proof and Object Damage-proof

9. Intelligent early warning module is designed to automatically eliminate common faults and hazards for environmental early warning, which makes the warehousing system work stably.

Fourth, the benefits of shuttle warehouse equipment

1. More and less samples: food, beverage, chemical industry, tobacco and other industries with large batches of single varieties and relatively single items

2. Cold Storage Operation: Reducing Low Temperature Operation Time, Improving Working Efficiency and Safety

3. Time limit management: Warehouses with strict requirements for batches of goods and first-in-first-out operation management

4. Increasing storage capacity: Storage space is limited and warehouses need to maximize the use of space

Fifth, Installation Site of Shuttle Stereo Warehouse

1. Kojie Installers are trained strictly before installing power battery warehouse, logistics conveyor line site, safe operation and installation personnel into the site.

2. Establishing Safety Management and Safety Organization

3. Making Safety Measures for Construction

4. Arrange safety management personnel for safety management and safety monitoring.

Provide intelligent warehousing logistics equipment solutions business.

Provide intelligent warehousing logistics equipment solutions business. Continue to explore the possibility of user experience

Continue to explore the possibility of user experience Our service is not a slogan, a concept or an advertisement. Our service is serious.

Our service is not a slogan, a concept or an advertisement. Our service is serious. You are welcome to call for information or appointment.

You are welcome to call for information or appointment.